- Industry: Commercial Office Building – 40 floors

- Application: 1500-ton HVAC Cooling Tower System

- Problem: Frequent strainer blockages and high chiller approach temperatures due to severe biofouling caused by difficulties during new construction commissioning

- Solution: System piping and equipment cleaned using patented bioeXile® cleaner in conjunction with an EPA registered biocide

- Result: bioeXile® cleaning procedure eliminated strainer blockages and returned chiller approach temperatures returned to design

Prior State (Condition)

Shortly after the handover of a newly constructed building, the condenser water system strainers began clogging with (biofilm) deposits, restricting water flow and compromising cooling efficiency.

With hundreds of strainers requiring frequent cleaning and maintenance, the issue quickly escalated. Increasing biocide feed rates and frequency failed to resolve the problem.

As ambient temperatures rose, the strainers required even more frequent cleaning—in some areas, as often as once a week. Meanwhile, chiller condenser approach temperatures climbed, leading to higher-than-expected energy consumption and increased operational costs.

Proposed State and Justification (Recommendation)

The objective was to restore the system to its original design parameters, reducing energy consumption and ensuring optimal operational efficiency.

To achieve this, Chem-Aqua recommended a full system clean and flush, incorporating its patented biofilm disruptor, bioeXile, alongside a tailored biocide programme.

Corrective Actions

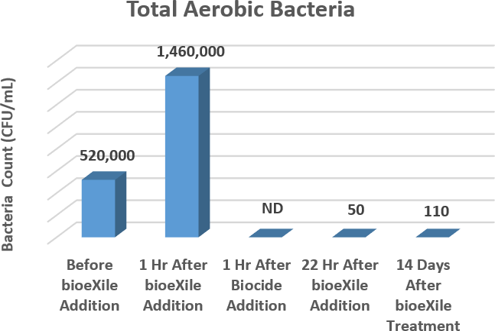

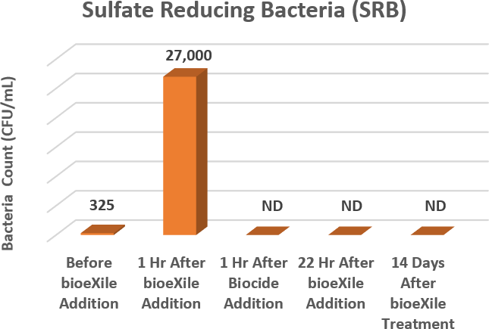

- The system was dosed with bioeXile, circulating through all piping and equipment, including cooling towers, chillers, and heat exchangers.

- An oxidising biocide (chlorine) was introduced to control microbiological activity released during biofilm disruption.

- The cooling towers were drained, cleaned, and disinfected before system start-up.

- Engineering and operational controls were implemented in collaboration with the customer to manage dead legs and ensure routine circulation in low-flow areas.