bioeXile® restores system cleanliness in no time!

- Industry: Plastic Packaging for Food Industry

- Application: Cooling System

- Problem: Cooling system cleans are disruptive for the production. The aim was to make these cleans more effective and reduce their frequency

- Solution: Patented bioeXile® product added to the Legionella cleaning and disinfection procedure released large amounts of sludge and biofilm

- Results: Effective removal of harmful bacteria underneath the biofilm. Downtime kept to minimum.

Biofilms create issues in cooling system by reducing significantly the heat transfer, as well as harboring pathogens bacteria (such as Legionella and Pseudomonas) and providing an ideal environment for under deposit corrosion to occur (MIC, Microbiologically Induced Corrosion). MIC can be very costly by reducing equipment life significantly.

Chem-Aqua Solution

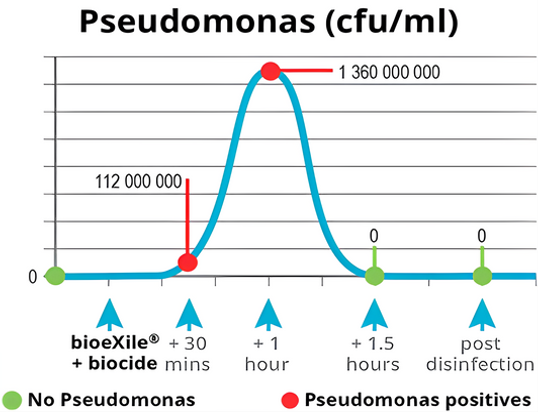

bioeXile unique formula removed a lot of sludge from the system and penetrated biofilm, releasing high amounts of bacteria. This confirmed that biofilm was indeed present in the system despite good historical microbiological counts. Standard dip slides are, therefore, not the best indication of system cleanliness or of microbiological control. bioeXile was very efficient in removing the biofilm while working in combination with our biocide to kill the dislodged bacterial population instantaneously (see graph below) and restoring the system to total working capacity. Future online use of bioeXile will ensure that the system stays clean for longer.

Problem

Our customer, a European leader in manufacturing plastic trays for the food industry, values high productivity while focusing on recyclability, sustainability and safety. The efficiency of the cooling system is of ultimate importance to them to ensure continuous production, but a busy industrial environment means that the cooling towers can get dirty quickly and need regular cleans. Being able to reduce the frequency of those cleans, by making them more effective is of prime importance to them.

A comprehensive water treatment program was in place, with consistent good level of biocide residual and no Legionella positives, leading to believe that the cooling system was under control. However, Chem-Aqua suspected some biofilm in the system and proposed a thorough bioclean by adding our new patented biodispersant product bioeXile to the normal clean and disinfection procedure.

System cleaning and chlorination supplemented with bioeXile® removed harmful Pseudomonas and SRBs

- Very high amounts of Pseudomonas bacteria were released in the water, whilst there was no signs of Pseudomonas priorly in the system, confirming the presence of a biofilm.

- SRB’s which are also indicative of biofilm and linked to Microbiologically Induced Corrosion tested positive before the clean. Post clean testing demonstrated they where removed.

- Chlorine levels were depleated very fast due to the large amount of bacteria released during the clean and were supplemented as required.

- Chem-Aqua’s cleaning method with bioeXile® allowed a thorough clean of the system as proven by the high amount of sludge and bacteria removed.

- The identification of a large Pseudomonas population demonstrated that biofilm was present and can not be detected by just monitoring the Total Bacteria count in the water.

- Simultaneous addition of bioeXile® and biocide allowed a controlled release of bacteria in the towers (keeping safety in mind) while keeping the down time associated with the cleaning operation minimum.